Hey there! I've been working in a swimwear factory for quite a few years now, and I'd love to share my experiences about the cutting process with you all. When I first started, I was completely lost, but now? Well, let's just say I could probably do this in my sleep! Let me walk you through our daily adventures in the cutting department.

First Steps: The Art of Pattern Board Inspection

Oh boy, do I remember my first rookie mistake - jumping straight into cutting without checking the pattern board! The senior cutter just shook his head and smiled, saying, "What's the rush, kid?"

That lesson came back to bite me pretty quickly. The sizes were all wrong, and I had to redo everything. Talk about a humbling experience! Now, the first thing I do when I get a pattern board is:

Count the total pieces needed (can't mess up those numbers!)

Check the size ratios (how many S's, how many M's)

Count the pattern pieces

Most importantly, measure every single piece

Trust me, these "time-consuming" steps actually save tons of time in the long run. Redoing work? Now that's what I call time-consuming!

Fabric Relaxation: Patience is a Virtue

When it comes to fabric relaxation (we call it "laying out"), it's all about patience. I often joke with newcomers, "Our job's secret ingredient? Patience!"

Different fabrics are like different personalities - they each need their own special treatment:

Polyester is the easy-going one - just a few hours and you're good to go

But nylon or high-spandex content? Those are the divas - they need 24-48 hours minimum

There was this one time when we were rushing an order, and a newbie tried to skip this step. Let's just say those swimsuits looked more like children's sizes by the time they were done! Since then, I've learned that good things come to those who wait.

Spreading: The Two-Person Tango

Now, spreading fabric is where the real fun begins. For small batches, we do it manually, and it's like a perfectly choreographed dance between two people. My partner Wang and I are known as the "Dynamic Duo" around here!

Our secret sauce?

One person keeps it straight while the other pulls

Always leave 3-5cm extra (better safe than sorry!)

One edge must be perfectly straight - that's non-negotiable!

Sure, we have automatic spreaders for big orders now. They're efficient, but they lack that human touch. Still, that's progress for you!

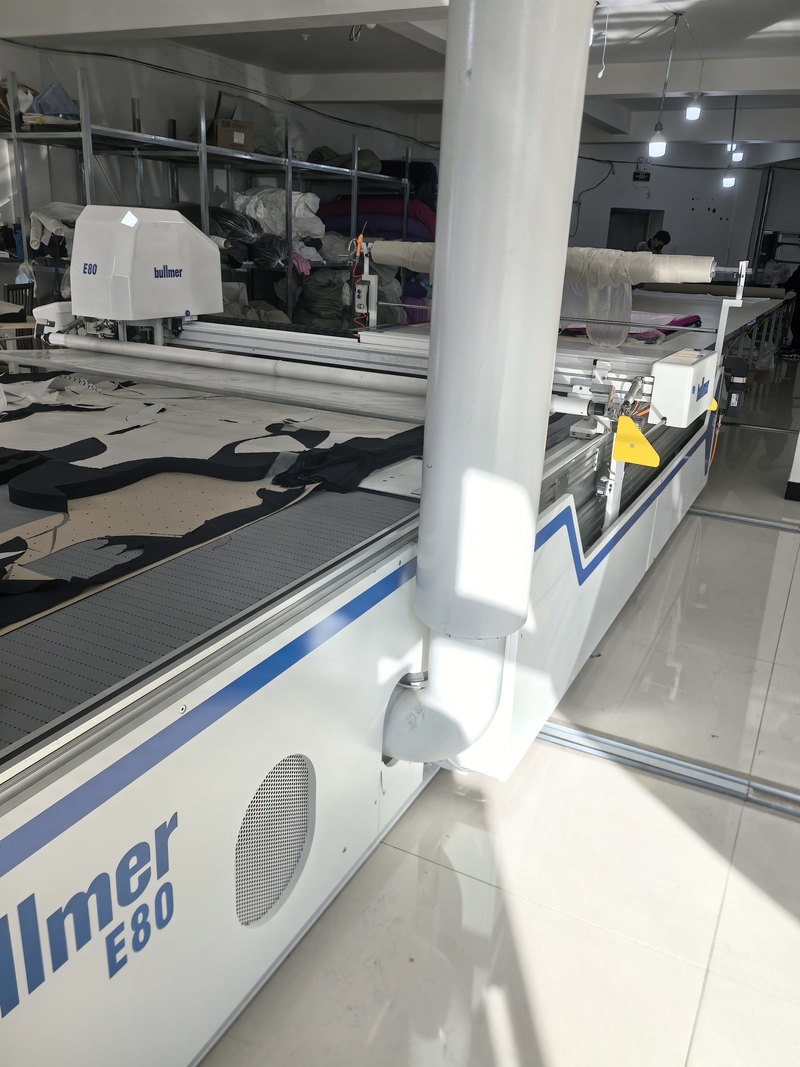

Cutting: Man vs. Machine

When it comes to cutting, this is where skill really shines. Yes, we have automatic cutters now, but there's still something special about manual cutting.

Just last week, we had this super soft fabric that the machine couldn't handle properly. Hand-cutting saved the day! It took longer, but the quality was spot-on.

That said, for large orders, machines are a lifesaver. Just remember:

Leave 3cm margins all around

Keep 0.1cm between patterns (learned that one the hard way!)

Piece Sorting: Where the Devil's in the Details

Sorting pieces always keeps me on my toes. It's where small mistakes can turn into big problems.

Here's my little trick:

S sizes in one pile

M sizes in another

Main fabric separate from lining

Labels on everything!

I nearly mixed up M and S sizes once - caught it just in time! That would have been quite the disaster.

Bundle Tying: The Final Checkpoint

Bundle tying is our last line of defense. Seems simple, but there's a technique to it:

Hand-tie for 10-20 layers

Machine-tie for 50-100 layers

Always keep size labels visible for the next department

Lessons Learned

After all these years, my biggest takeaway is this: what looks simple on the surface often has layers of complexity. Every step matters, because one mistake can mean redoing everything.

I love sharing these tips with newcomers. Seeing them grow and improve gives me such satisfaction. Maybe that's the best part of this job - helping others avoid the mistakes I made!

Final Thoughts

Writing this, I realize how much I've come to love this job. Sure, it can be tiring, but seeing beautiful swimwear come to life through our hands? That feeling is priceless.

I hope these insights help anyone interested in swimwear cutting. Remember, in this industry, attention to detail and patience are your best friends! Feel free to reach out if you have any questions - I'm always happy to help!

If you are interested in the workflow of a swimwear factory, feel free to explore our other blog posts on our website, such as: