The swimwear business is growing quickly and doing very well.

The market is expected to grow from £21.54 billion in 2024 to £29.27 billion by 2033.

This means it will grow by 3.4% each year.

This fast growth shows how tough the competition is. To succeed, brands need to make great products, be creative, and produce more efficiently.

Working with good swimwear manufacturers does more than improve your business. It also makes your brand look reliable to investors, customers, and the market. A trusted partner brings knowledge, strong supply chains, and trust. They help you meet demand and keep quality high.

Picking the right swimwear manufacturers can turn your ideas into real products. Their importance in building a brand’s success is huge.

Key Takeaways

Pick a trustworthy manufacturer to improve your swimwear's quality. Talking clearly about goals helps avoid problems and ensures on-time production.

Support the environment by choosing manufacturers using eco-friendly materials. This draws in modern buyers and boosts your brand's image.

Keep up with trends by partnering with flexible manufacturers. This helps you try new designs and quickly meet customer needs, keeping your brand popular.

The Role of Swimwear Manufacturers in Brand Success

Ensuring Quality and Consistency

A swimwear brand cannot succeed without good quality and consistency. Customers want swimwear that fits well, feels nice, and lasts long. Swimwear manufacturers are key to meeting these needs. They use smart quality checks to ensure every item is top-notch. For example, they test fabrics to see if they stretch, last, and resist chlorine or saltwater. This careful work helps you sell products that people trust.

Consistency matters just as much. Customers expect the same great quality every time they buy. Manufacturers make this happen by using steady processes and dependable materials. By choosing a manufacturer that focuses on quality and consistency, you can gain loyal customers and improve your brand's image.

Tip: Always share your quality goals with your manufacturer. This helps them match your brand's standards.

Driving Innovation in Design and Materials

Swimwear is no longer just for swimming; it’s now a fashion trend. To stay ahead, you need unique designs and materials. Swimwear manufacturers help by trying out new ideas. They create fabrics that dry fast, block UV rays, and resist chlorine. Using eco-friendly materials also attracts customers who care about the planet.

Creative designs are also important. Manufacturers often team up with designers to make fresh styles and patterns. For example, using design thinking has helped brands understand customers better and create smarter solutions. This teamwork leads to exciting products that stand out. By working with a creative manufacturer, you can launch trendy items that grab attention.

Note: Ask your manufacturer about their experience with new materials and fashion trends.

Scaling Production to Meet Growing Demand

As your swimwear brand grows, you need a manufacturer who can produce more. Swimwear manufacturers do this by improving their processes and using better tools. They track things like speed and output to keep quality high while making more products. For instance, fixing broken machines helped one manufacturer make more items without buying new equipment.

Scaling up also means managing resources wisely. Manufacturers save money by making deals with suppliers and buying in bulk. These methods help you meet demand without raising prices too much. They also check things like defect rates to keep quality steady as production grows.

Tip: Set clear goals with your manufacturer and track progress using numbers like production rates and efficiency.

Case Studies: Swimwear Brands That Succeeded with the Right Partner

Hunza G: Bringing Back a Classic with Celebrity Help

Hunza G, a British swimwear brand, made a comeback by teaming up with skilled swimwear manufacturers. First famous in the 1980s for its crinkle-stretch fabric, the brand lost popularity until it was revived in 2015. By working with manufacturers who valued quality and creativity, Hunza G updated its iconic fabric for modern tastes.

The partnership ensured steady production of top-quality swimwear that appealed to younger buyers. Celebrities like Kim Kardashian and Hailey Bieber promoted the brand, making it more popular. These endorsements worked because the product’s quality matched the buzz. The manufacturers helped Hunza G increase production while keeping its unique fabric special, meeting the rising demand.

Triangl: Growing a $200 Million Brand with Smart Choices

Triangl, an Australian swimwear brand, became famous for its simple and affordable designs. Its neoprene bikinis stood out with bright colours and clean looks. The real success came from partnering with swimwear manufacturers who were experts in fabrics and efficient production.

The founders tested their designs through sampling before selling them. This ensured every product met customer needs. The manufacturers supported this by offering custom designs and strict quality checks. Their teamwork helped Triangl secure funding and grow quickly. In just a few years, the brand was worth $200 million, proving how the right manufacturing partner can turn small ideas into big success.

Moana: Growing 69% with Social Media and Partnerships

Moana Bikini, another Australian brand, used social media and smart partnerships to grow fast. By working with swimwear manufacturers, the brand focused on creating trendy, Instagram-worthy designs. These manufacturers offered white-label services, helping Moana launch new collections quickly and stay trendy.

Social media was key to Moana’s success. Platforms like Instagram helped the brand show off its designs and connect with buyers. This, along with efficient production, led to a 69% rise in revenue. The manufacturers ensured Moana could meet the demand from its social media campaigns while keeping quality high.

Infamous Swim: Doubling Sales with Smart Marketing and Manufacturing

Infamous Swim, a family-focused swimwear brand, doubled its sales by matching its marketing with its manufacturing. The brand is known for its matching swimwear for parents and kids. To deliver this, Infamous Swim partnered with swimwear manufacturers skilled in fabric and printing.

These manufacturers made sure the swimwear was stylish, durable, and comfy. They also helped lower costs, allowing the brand to offer good prices without losing quality. Infamous Swim’s marketing highlighted these features, connecting well with its audience. This led to higher sales and loyal customers.

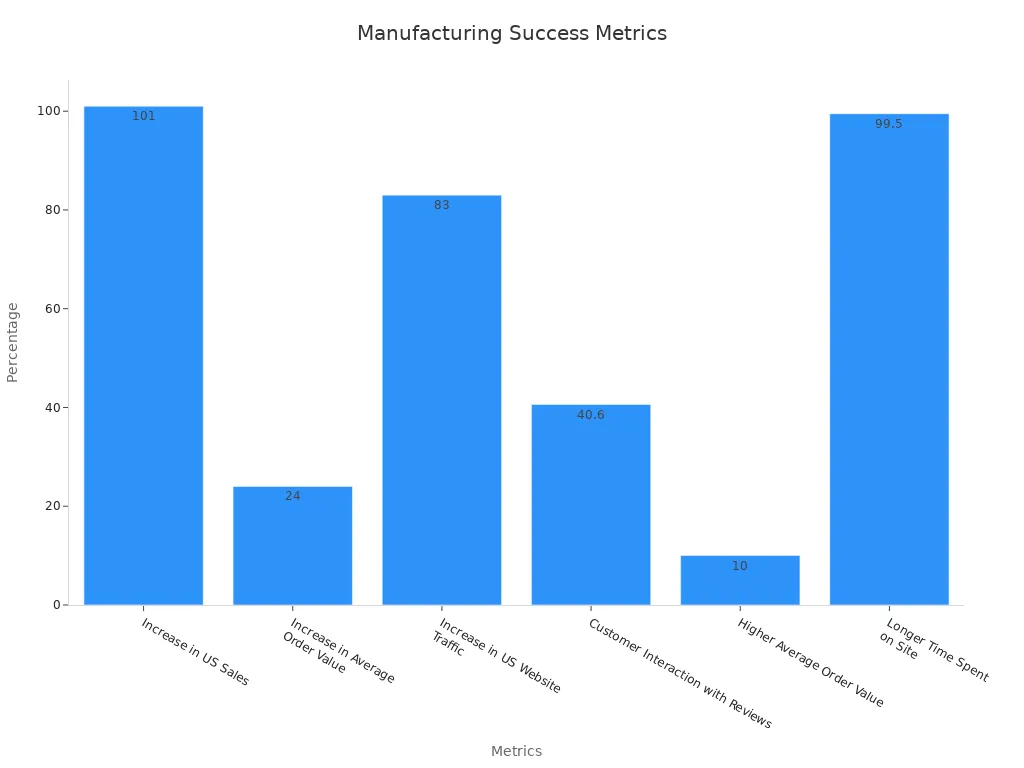

Did You Know? Brands that work with experienced swimwear manufacturers often see big improvements. For example, a study showed a 101% rise in US sales, 83% more website visits, and a 24% higher average order value.

These stories show how the right manufacturing partner can make a big difference. Whether it’s growing production, creating new designs, or keeping quality high, the right partner can help turn ideas into success.

Key Takeaways for Aspiring Swimwear Brands

The Importance of Collaboration and Communication

Working closely with your manufacturing partner can improve your swimwear brand. Clear communication helps match your ideas with production steps. Reliable manufacturers help you meet deadlines and keep quality high. Talking about minimum order quantities (MOQs) and timelines early prevents problems and keeps your goals clear.

Sharing honest stories builds trust with customers. For example, brands like AquaChic Apparel attract eco-friendly buyers by showing their care for the planet. Teaming up with green organisations makes your brand look trustworthy and responsible.

Tip: Work with manufacturers who value talking openly and being flexible. This can boost online swimwear sales by up to 25%.

Prioritising Sustainability and Ethical Practices

Caring for the environment is now essential for swimwear brands. Eco-friendly practices attract modern buyers. Manufacturers using recycled materials and safe dyeing methods lower harm to nature. For example, biodegradable swimwear breaks down in a few years instead of hundreds.

Regular Swimwear | Eco-Friendly Swimwear | |

|---|---|---|

Water and Chemical Use | Uses large amounts | Recycled materials save water |

Toxic Waste Release | Pollutes water during dyeing | Eco dyes cause less pollution |

Decomposition Time | Takes hundreds of years | Breaks down faster |

Waste Disposal | Ends up in landfills/oceans | Recycling reduces waste |

Working with manufacturers who care about sustainability improves your brand’s reputation. TY Fashion, for instance, overcame tariff issues by focusing on natural fibres and eco-friendly swimwear.

Adapting to Market Trends with a Flexible Partner

The swimwear market changes quickly. Flexible manufacturers help you follow trends and grow production smoothly. Skilled manufacturers handle small orders, letting you test designs without wasting resources.

Teaming up with local artists mixes global styles with local traditions, creating unique collections. This approach supports cultural sharing and highlights handmade work. Tidal Trends Swimwear, for example, worked with influencers to increase sales and trust in the eco-friendly swimwear market.

Tip: Pick manufacturers who know fabrics like Lycra and polyester blends. Their skills ensure your products meet customer needs and stay trendy.

The right swimwear maker can help your brand succeed. Working together brings many advantages:

Better market reach and stronger brand image

Lower expenses and fewer business risks

Chances to reduce pollution and waste

For instance, Fast Retailing helped its suppliers during COVID-19. This support boosted profits and allowed worldwide growth. Pick carefully, and your ideas can grow.

FAQ

What should you look for in a swimwear manufacturer?

Look for quality, growth potential, and creativity. Make sure they understand your brand's goals and can deliver reliable products. Ask if they have experience with eco-friendly materials and current fashion trends.

Tip: Visit their factory to check their production skills and ethical standards.

How can you ensure your designs stay unique?

Work closely with your manufacturer to keep your ideas safe. Use special patterns, one-of-a-kind fabrics, and unique branding to make your swimwear stand out from others.

Is it necessary to choose a local manufacturer?

Not always. Local manufacturers are easier to talk to and have lower delivery costs. But international ones might have better tools or cheaper options. Pick based on what matters most to you.

Note: Weigh cost savings against quality and ethics when choosing a manufacturer.Image Source: pexels