Swimsuit manufacturers are a vital part of a thriving industry worth nearly $13 billion globally and continuing to grow steadily into 2026. Swimwear might look simple, but making it involves complex steps. These include picking the right fabric, creating patterns, using specialized design techniques, and maintaining strict quality control.

If you're considering starting your own swimwear brand, check out our [How to Start a Swimwear Brand in 2026? (A Complete Guide)] to learn more about the steps involved in building a successful swimwear business.

Many fashion brands find it hard to pick the right swimwear manufacturers. They need to think about minimum order quantities, eco-friendly practices, and production capacity. Some manufacturers let you order as few as 50 pieces, while others want nowhere near that number - a fact many brands miss. The best swimsuit manufacturers can be found both locally and overseas, and each option comes with its own benefits and challenges. A brand's reputation depends heavily on how well custom swimsuit manufacturers deliver on key aspects like consistent sizing and the fabric's ability to stretch and bounce back.

Why fashion brands often choose the wrong swimsuit manufacturers

Fashion brands often make critical mistakes when picking swimsuit manufacturers. These errors can sink their success before they even get started. Most problems come from not understanding how swimwear production works and expecting too much from manufacturers.

Lack of research and due diligence

Brands rush to partner with manufacturers without doing their homework. Low prices and quick turnaround times look tempting. Finding suppliers online seems easy, but good SEO and ad spending don't guarantee quality products or reliable delivery.

New brands fall prey to what people in the industry call "the Wild West" of online supplier sourcing. They miss these warning signs when picking swimwear manufacturers:

Manufacturers who hide behind NDAs and can't provide references from existing clients

Facilities with outdated equipment lacking specialized machines (like flatlock machines essential for swimwear)

Unclear communication about production capabilities and timelines

Good research needs more than website browsing. Factory visits or virtual tours show what's really happening. One brand learned this lesson after visiting potential manufacturers in New York's Garment District. They saw "posters on walls noting that fabric stacked to the ceiling wasn't up to fire code".

Over-prioritizing cost over quality

New brands with tight budgets feel the pull to pick the cheapest swimsuit manufacturers. This strategy usually backfires badly. A swimsuit that sells for $200 typically costs $50 to produce. Cutting costs on this thin margin creates serious quality problems.

Material quality shapes both price and performance. Good swimwear fabrics must handle chlorine, salt water, UV rays, and constant stretching. Quality construction needs strategic lining and tighter stitching—12 stitches per inch instead of 8 in cheaper options.

Brands that pick manufacturers based on price alone learn a hard lesson. Poor-quality materials can cause skin irritation and allergic reactions. These problems hurt the brand's reputation and boost return rates. The cost ends up higher than investing in better manufacturing from day one.

Ignoring minimum order quantity (MOQ) constraints

Fashion brands often mess up by not understanding or respecting minimum order quantities. MOQs exist for good reasons—they help manufacturers optimize processes, use resources well, and keep costs down.

Some new brands follow bad advice: "just agree to whatever order quantity the factory says they need and then negotiate it lower once it's time for production". This approach fails every time. Industry experts warn, "I promise if you do this, it will be a disaster. The factory will either dump you or jack up your prices".

Ignoring MOQs creates more problems than just angry manufacturers. Higher MOQs can limit your ability to offer different options, especially if you're new or small. Too few units can lead to stockouts, lost sales, and unhappy customers.

MOQs vary between manufacturers. Some want orders of 100,000 units, while others might work with just 300 units. Brands working with very low MOQs (around 100 units) pay much more per unit. This changes their profit math completely.

Smart brands understand MOQs before making plans. One expert puts it well: "If a factory MOQ is too high for you right now, that's ok; maybe you can work with them in the future". Starting with honest communication builds lasting partnerships.

Common red flags in swimwear manufacturers

Fashion brands can save themselves from disastrous manufacturing partnerships by spotting warning signs early. A brand's reputation depends on catching red flags in swimsuit manufacturers before signing contracts. This helps avoid quality issues, missed deadlines, and damage to the brand's image.

No sample policy or poor sample quality

Reputable swimsuit manufacturers know sampling isn't optional. They follow a clear sampling process to test designs before bulk production. This vital step makes sure your designs look and fit right on real bodies, which reduces returns and negative reviews. Industry experts say, "Never skip this step! It's very important to be proactive rather than reactive".

The first samples reveal design flaws that need fixing. Professional manufacturers use these samples to find problems with design, materials, and fit. A manufacturer's refusal to provide samples or charging too much for them raises a red flag. Poor sample quality points to bigger production issues down the line.

The best manufacturers create "prototypes" that fit specialists check thoroughly. Samples with obvious defects like uneven stitching, puckered fabrics, or wrong sizing show what bulk orders might look like later.

Unclear communication or vague timelines

Clear communication is the life-blood of successful manufacturing partnerships. Quick and clear exchanges help prevent errors and keep everyone's expectations in line. Be wary of manufacturers who answer every question with "no problem" without giving real feedback.

Such shallow responses hint at a lack of understanding that will hurt quality. Watch out for these warning signs:

Slow responses to your first messages

Unclear or changing production schedules

No explanation of quality control steps

Reluctance to show previous work

Partners who can't communicate well produce poor results. One industry source points out, "If you try and don't find improvement and effort from your maker, this will repeatedly cause problems and prevent growth, not to mention the constant stress to which you and your business will be subjected".

Lack of transparency in sourcing and labor practices

The swimwear industry faces more scrutiny about ethical production and sustainability. Good swimsuit manufacturers openly share details about their supply chain, material sources, and labor conditions.

Hidden practices often lurk behind manufacturers who refuse transparency. Ethical production goes beyond materials to include worker treatment, fair pay, safe conditions, and reasonable hours. Manufacturers who dodge questions about their practices or material sources send up major warning signals.

Research shows 94% of fashion brands don't share information about their work with communities affected by climate issues. This lack of openness can hide unfair practices like low wages, unsafe conditions, and child labor.

Quality-focused manufacturers test and inspect at every production stage. They check fabric quality, cutting accuracy, sewing, and final product fit. Those who won't explain these steps likely lack proper quality controls.

Swim brands build customer trust by being open about material sources, manufacturing locations, and worker conditions. Choosing manufacturers who value transparency helps customers make informed choices.

How poor manufacturer choices impact your brand

Poor swimsuit manufacturer choices can wreck your brand's success. Small manufacturing mistakes that seem harmless at first can quickly grow into major business problems. These issues affect everything from customer happiness to your bottom line.

Inconsistent sizing and fit issues

Getting sizes right is one of the hardest parts of making swimwear. Our research shows that manufacturers who lack proper grading skills create uneven sizing that makes customers unhappy and increases returns. Many swimwear brands have trouble with prototype development because they can't physically check products from overseas manufacturers.

Getting the right fit becomes harder as brands notice their customers' different body shapes. Good swimsuit manufacturers use advanced sizing technology and data to better understand body measurements. Many manufacturers fail to use these tools properly.

Even 20-year old brands face these problems. A swimwear company found that their TYR one-piece elastic broke after just six months of use. These problems come straight from poor quality control at the manufacturer level.

Delayed launches and missed seasons

Supply chain problems can seriously hurt swimwear brands' launch schedules. Over the past few years, global supply chain disruptions have exposed major weaknesses that still affect brands in 2026. Each day of supply chain disruption adds 5-7 days of cargo movement delays. Some delays need up to a month to fix.

These timing problems hurt more in the seasonal swimwear market. Inamorata learned this the hard way in a previous season when they couldn't deliver Black Friday orders. The brand had to give full refunds after months of delays.

Brands that lack clear manufacturing schedules often end up in this situation. Missing just one summer season can destroy a swimwear brand's yearly revenue because the selling window is so short.

Brand reputation damage from low-quality products

Bad materials create angry customers. Cheap fabrics and dyes can irritate skin and cause allergic reactions. This leads to bad reviews and complaints on social media. These quality issues hurt brand reputation and make more people return products.

Customers who buy low-quality swimwear often deal with:

Discomfort from bad fit and poor support

Products that stretch, fade, or fall apart after little use

Poor coverage that leads to embarrassing wardrobe problems

Quality control failures are the biggest problem in the manufacturing process. Good swimsuit manufacturers use multiple checkpoints. They check fabrics, detect metal for safety, do detailed quality checks during production, and create final inspection reports following AQL 2.5 standards.

Cutting corners on manufacturing quality costs more than investing in good production processes. Customers now expect sustainable and ethical production. Choosing the wrong manufacturers creates reputation damage that takes years to fix.

What to look for in the best swimsuit manufacturers

Your ideal swimsuit manufacturing partner should go beyond simple capabilities. You need true craftspeople who will bring your vision to life. A careful selection process builds the foundation for a soaring win in a crowded market.

Experience with custom swimsuit manufacturing

The best swimsuit manufacturers share your creative vision and business goals. They have mastered swimwear-specific production techniques like working with stretch materials and building durable, comfortable seams. This specialized knowledge is vital to create high-quality swimwear that performs well against chlorine, saltwater, and UV exposure.

Your manufacturer should handle both current needs and future growth. The right custom swimsuit makers can scale production without compromising quality - a significant factor for growing businesses.

Strong quality control and tech pack adherence

Quality control determines your swimwear line's success. The best swimwear manufacturers test products at multiple stages:

Fabric inspection before cutting

In-line quality checks during assembly

Metal detection for safety

Final inspection following AQL 2.5 standards

These strict procedures help catch minor defects before products reach customers. Quality manufacturers spot problems and work with brands to make adjustments. This promotes continuous improvement and product consistency.

Sustainable and ethical production practices

Today's consumers value sustainability more than ever. Partnering with green-minded swimsuit manufacturers improves your brand's appeal. Look for manufacturers who use recycled materials like ECONYL® (regenerated nylon from fishing nets and ocean plastics) or REPREVE (made from plastic bottles).

Ethical production goes beyond materials to worker treatment. Good swimsuit manufacturers ensure fair labor practices with adequate wages, safe conditions, and reasonable hours. Being transparent about these practices builds trust, as customers often make buying decisions based on ethics.

Selecting manufacturers who excel in these three vital areas helps your swimwear brand deliver exceptional products that last.

Steps to avoid choosing the wrong manufacturer

Choosing the right swimsuit manufacturer needs careful screening to avoid mistakes that can get pricey. A few key steps before partnering with a manufacturer will protect your brand from potential problems.

Start with a small test order

A smaller order helps you assess a manufacturer's capabilities without putting too much money at risk. This method gives you a ground picture of their quality control, communication and delivery reliability.

"Test runs are invaluable for revealing the truth about a manufacturer's capabilities," notes industry experts. A small original investment of 100-300 pieces shows you what might go wrong while limiting your financial risk. This approach also shows manufacturers you take quality standards seriously before scaling up production.

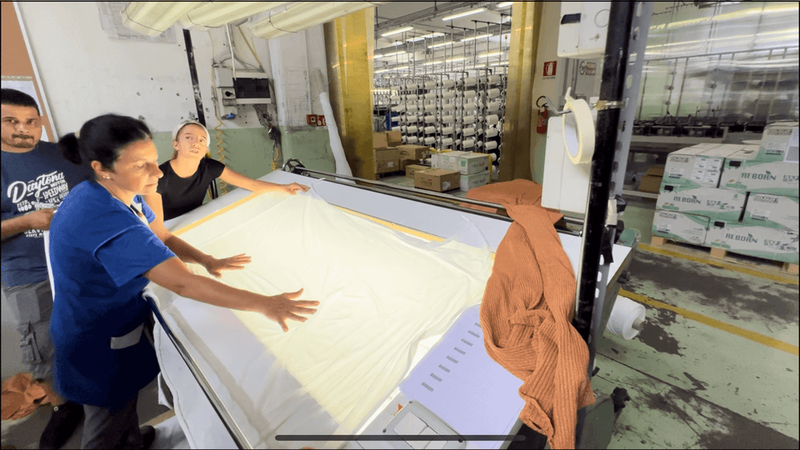

Visit the factory or request a virtual tour

You need to see operations firsthand. Physical visits to swimwear manufacturing facilities show vital details about working conditions, equipment quality, and production capabilities that websites and emails miss.

During factory visits, look for:

Specialized equipment like flatlock machines (essential for swimwear)

Clean, organized production environments

Quality control checkpoints throughout the process

Worker safety conditions and overall facility management

Virtual tours work well when overseas travel isn't possible. These detailed virtual inspections reveal a lot about a facility's capabilities and standards.

Ask for references and past client reviews

Good custom swimsuit manufacturers share references from current or previous clients readily. One industry source emphasizes, "Talk to other businesses that have used the manufacturer's services in the past. Ask about their experience and whether they would recommend the manufacturer."

Reach out to these references directly instead of going through the manufacturer. Ask about their response time, deadline management, quality consistency, and how they handle problems. Reliable bathing suit manufacturers know that being open guides them toward better long-term partnerships.

These verification steps protect your brand's reputation from potential manufacturing problems effectively.

Conclusion

Your fashion brand's success or failure in this competitive market ended up depending on choosing the right swimsuit manufacturer. Our research shows that successful manufacturing partnerships are built on detailed research, quality standards, and realistic MOQ expectations. Brands can avoid getting into pricey mistakes and reputation damage by spotting warning signs early - from poor samples to unclear communication or questionable labor practices.

Leading swimwear brands without doubt take a systematic approach to picking manufacturers. They don't rush decisions based just on price. Instead, they assess potential partners through test orders, factory visits, and reference checks. This careful approach pays off with consistent sizing, timely launches, and quality products that keep customers coming back.

Finding the perfect swimsuit manufacturer takes considerable work, but time invested brings rewards. Quality manufacturing collaborations become valuable assets that expand with your brand. Your choice of manufacturer directly shapes your brand's image - green practices, ethical standards, and production quality influence how customers see you.

Success in swimwear comes from understanding that manufacturing goes beyond basic transactions. Strong brands build genuine partnerships based on open communication, mutual respect, and shared quality standards. This mindset helps position your swimwear brand to thrive in an increasingly demanding market.

In 2026, with competition intensifying and consumers demanding higher quality and transparency, choosing the right swimsuit manufacturer is no longer optional—it’s a strategic advantage.

FAQs

Q1. What are some key factors to consider when choosing a swimsuit manufacturer? When selecting a swimsuit manufacturer, consider their experience with custom swimwear, quality control processes, adherence to tech packs, and sustainable production practices. It's also important to evaluate their communication, transparency about sourcing and labor practices, and ability to meet your minimum order quantities.

Q2. How can poor manufacturer choices impact a swimwear brand? Choosing the wrong manufacturer can lead to inconsistent sizing and fit issues, delayed product launches, missed seasonal opportunities, and damage to brand reputation due to low-quality products. These problems can result in customer dissatisfaction, increased returns, and significant financial losses.

Q3. What are some red flags to watch out for when evaluating swimsuit manufacturers? Be cautious of manufacturers with no sample policy or poor sample quality, unclear communication or vague timelines, and a lack of transparency regarding sourcing and labor practices. These warning signs often indicate deeper issues that could negatively impact your brand.

Q4. How can fashion brands avoid choosing the wrong swimsuit manufacturer? To avoid selecting the wrong manufacturer, start with a small test order to evaluate their capabilities, visit the factory or request a virtual tour to assess operations, and ask for references from past clients. These steps help ensure you partner with a reliable and quality-focused manufacturer.

Q5. Why is sustainability important in swimwear manufacturing? Sustainability in swimwear manufacturing is increasingly important as consumers prioritize eco-friendly products. Partnering with manufacturers who use recycled materials and employ ethical production practices can enhance your brand's appeal and build consumer trust, ultimately contributing to your brand's success in the competitive swimwear market.